Hydrocarbon spillage during maintenance work and turnarounds can have devastating effects on the environment, and remediation can be costly for refineries.

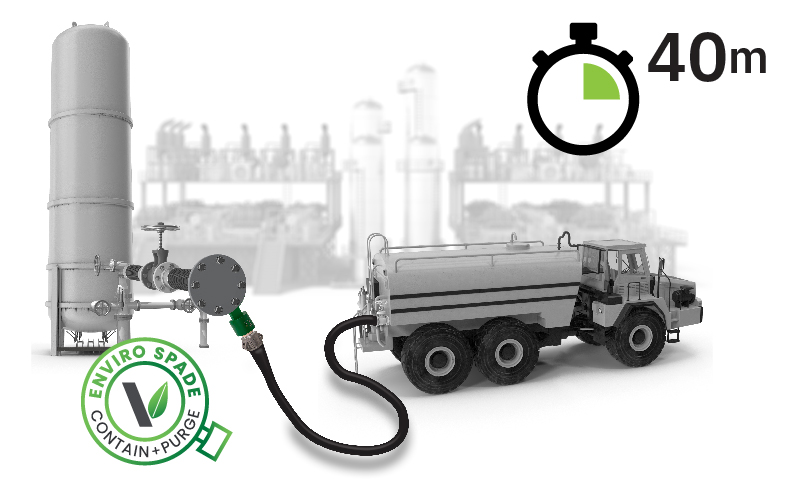

The Enviro Spade tool creates a spill-free environment for the transfer of residual hydrocarbon waste and other toxic materials from a tank/pipe/vessel/exchanger/tower to a vacuum truck.

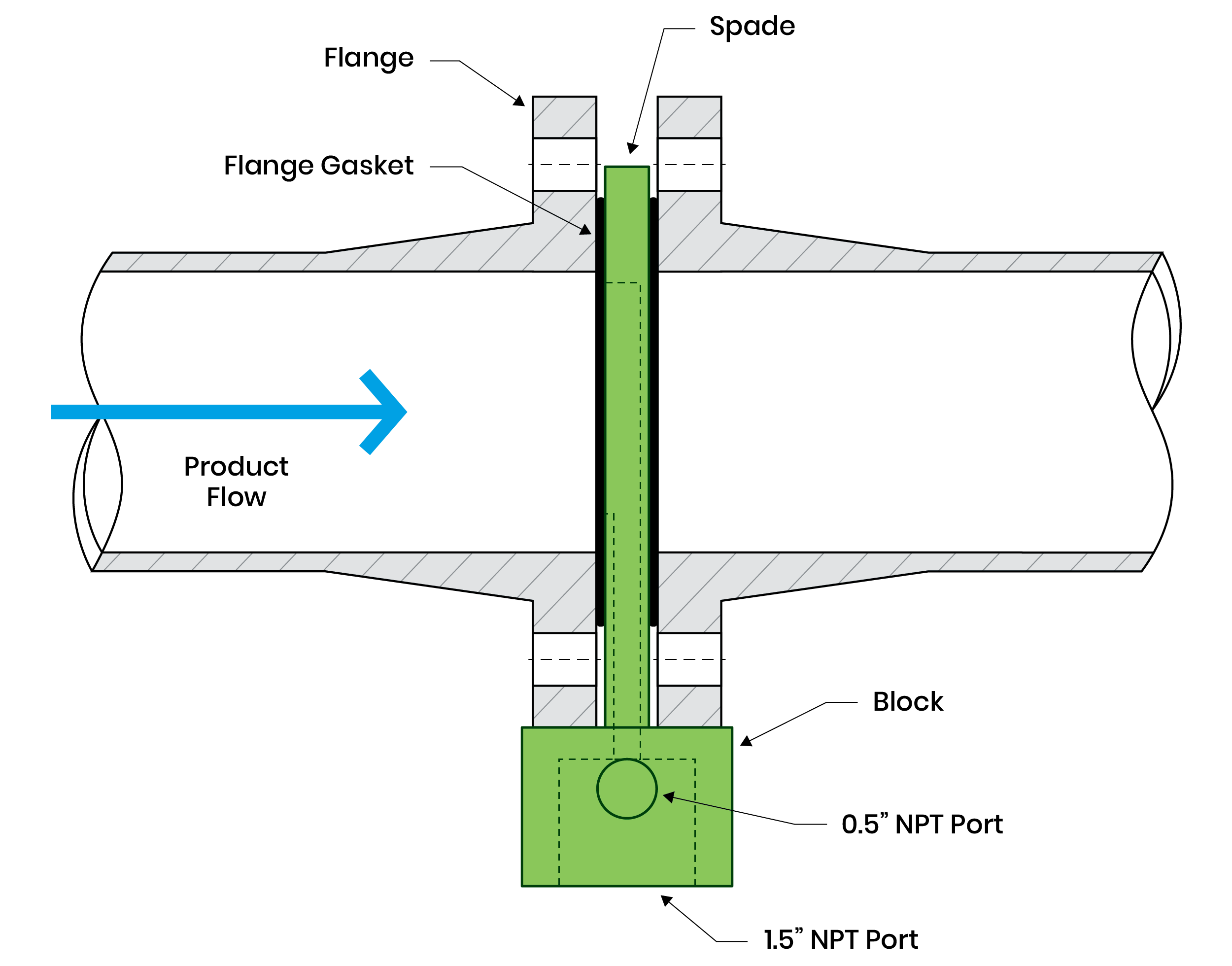

In the event of a leaking valve upstream, a paddle blind would block flow on both sides of your flange, creating pressure or fluid building up on one side of the flange. The Enviro Spade tool is a blind with venting capabilities, which would block flow on one side of the blind while allowing access to relieve or purge the other side of the blind.

In the event there is no valve on your pipe at the job location, the Enviro Spade tool can be installed to:

Vital’s focus was to create a safe tool with all-around ease of use. The Enviro Spade is unique in that it offers control over both containment and purge capabilities.

Vapour Phase Cleaning is an enhanced steaming method used to speed up the decontamination process. It works by injecting a small amount of chemicals (usually less than 1%) into the steam vapour just before it enters the system.

The specialized chemicals accelerate the cleaning process, target specific contaminants, and reduce overall cleaning time by as much as 60% to 70%. Vapour Phase Cleaning can be used with most types of process equipment, including reactors, columns, vessels (in general), heat exchangers, compressors, storage tanks, filters, piping, etc.

Generally emptying a carbon bin takes us about 4 hours. We were able to do the job within 40 minutes using Vital’s Enviro Spade.